This will release fluid and air trapped in the system. Were at wits end.

Expired Brand New Mcleod 96 04 Hydraulic Clutch Kit And

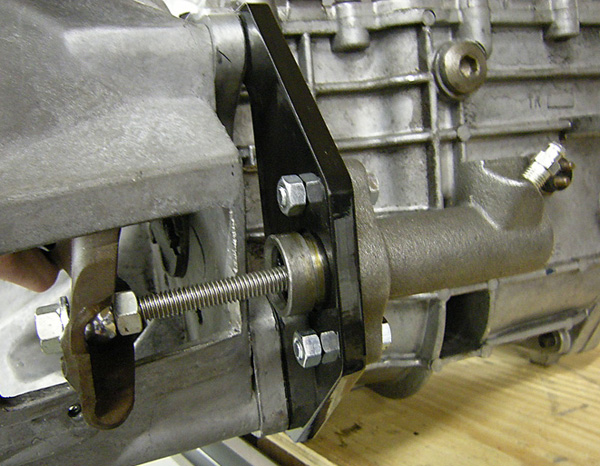

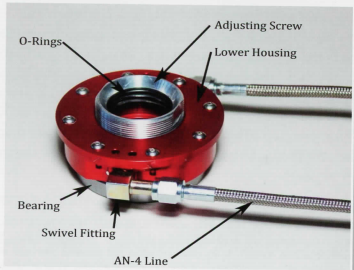

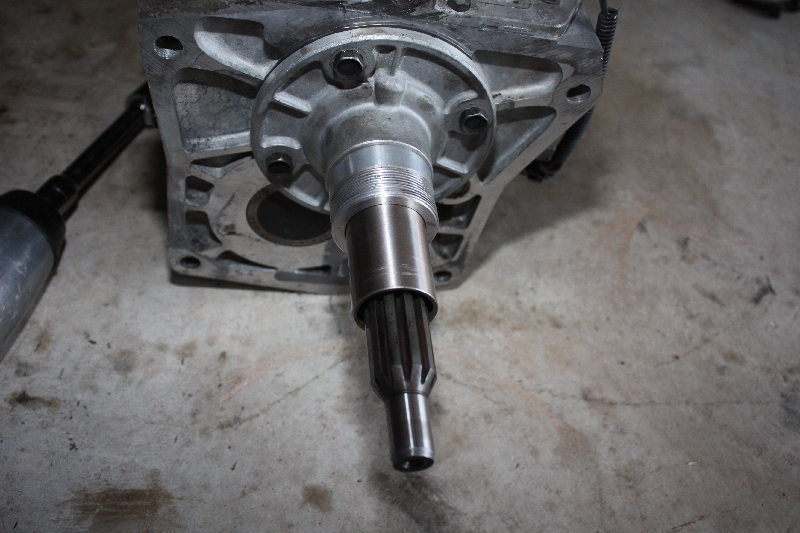

Mcleod hydraulic throwout bearing problems. Continue the bleeding process until all of the air is removed from the system. Let us know if you have any questions. The sloppiness in the threads is noticeable because you can wobble the throwout bearing by hand. After the master cylinder is filled bleed the bearing assembly. Symptoms of a bad throwout bearing. Since the slip on bearing actually threads onto a sleeve perhaps it is the tolerancing of the threads between the bearing and the sleeeve.

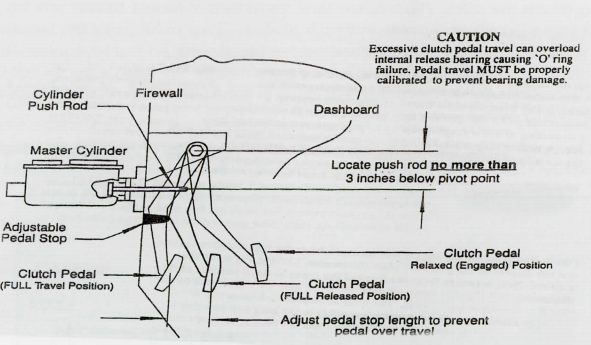

If you have any questions or concerns our tech lines are open at this time. The problem is that we never got any pedal resistance or even a twitch of movement at the throwout bearing after many many attempts at bleeding the system. When the driver releases the clutch pedal the hydraulic system is deactivated and the throwout bearing is pushed away by the diaphragm spring thus resuming contact between the clutch plate and the flywheel. It was not the fitting and we could not reproduce the leak. We would like to show you a description here but the site wont allow us. We appreciate all of our customers for their support during this difficult time.

Pump the pedal 3 to 4 times with the bleeder valve open and the end of the opening submerged in a cup partially filled with brake fluid. We could reproduce the leak when only 1 c clamp was on though as the piston would slightly tilt making a poor seal. Mcleod racing continues to fulfill assemble and ship product during this time. Tune in to watch chad and joe as they take you through the process of using our rebuild kits for our hydraulic throw out bearings 1300 and 1400 series. Mcleod tech suggested that maybe there was preload or lack of upward travel on the master cylinder pushrod not allowing the piston to retract far enough to get a full charge of fluid from the reservoir. 1 the seals of the bearing could be very sensitive to any angle ing of throwout bearing.

Then we put 2 c clamps on the throwout bearing piston so that we could lightly push the pedal confirm that it was the fitting leaking.