Page 1 of 2. Continue reading for the full comparison.

Epdm Vs Silicone A Simple Guide Knowledge Center

Epdm vs buna o ring. Has an operational temperature range of 40f to 250f 40c to 121c and a hardness range of 40 90 durometer. Rubber compounding is a very broad and technical field since basic rubbers or elastomers are mixed with various chemicals and. For the purposes of this article we will focus on just three common rubber types found in o rings and similar automotive seals. Temperature tolerance chemical compatibility and cost. Viton is the choice over buna for high temperature applications. Rubber properties neoprene epdm buna n silicone sbr butyl natural rubber gu.

As a sealing option the crucial difference between buna and viton is the temperature range the materials function in. Nitrile butadiene 30 f 250 f. The term buna n is really not much more specific than the term steel. Epdm viton or buna n. When comparing viton vs. Poor resistance to petroleum based fluids.

Animal and vegetable oils ozone strong and oxidizing chemicals. A synthetic rubber with excellent oil resistance and fair to good chemical resistance. Ethylene propylene 40 f 300 f. We offer three different premium gasket materials for our steel storage tanks. Selecting the proper gasket material can make a significant difference in the lifespan of the tank. About us success stories contact us.

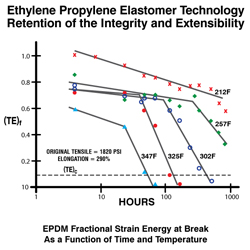

This popular o ring material family comparison shows basic rubber material family properties and performance plastic properties. Ep copolymers must be peroxide cured while epdm polymers can be cured via sulfur or peroxide. Epr specifically refers to ep copolymer while epdm refers to ep terpolymer. Family of rubber materials. What is viton a. When purchasing a bolted steel tank from superior tank customers have several choices of gaskets.

Rubber properties the chart below is intended to help in the material selection stage of designing rubber parts products. Viton seals hold indefinitely at temperatures up to 400f and can last up to 48 hours at temperatures up to 600f. Epdm or ethylene propylene diene monomer is widely used to make o rings washers and other sealing fittings in water and steam lines and in auto and truck cooling and brake systems. Epdm ethylene propylene diene. Epdm seals are resistant to mild acids detergents silicones glycols ketones and alcohols and can handle temperatures from minus 22 degrees fahrenheit up to. While this is important information in terms of o ring manufacturing this difference is transparent to the end user.

Note that each type is actually a family of rubber compounds. Excellent ozone chemical and aging resistance. Epdm which stands for ethylene propylene diene monomer has its own set of properties that make it an extremely popular o ring material. Buna n viton and epdm. Which seal for your application. O ring material quick reference guide rubber sealing materials.

Mineral oils and solvents aromatic hydrocarbons. O ring material family chemical compatibility temperature resistance and other properties all factor in to o ring material selection for an application. Epdm several factors must be considered.