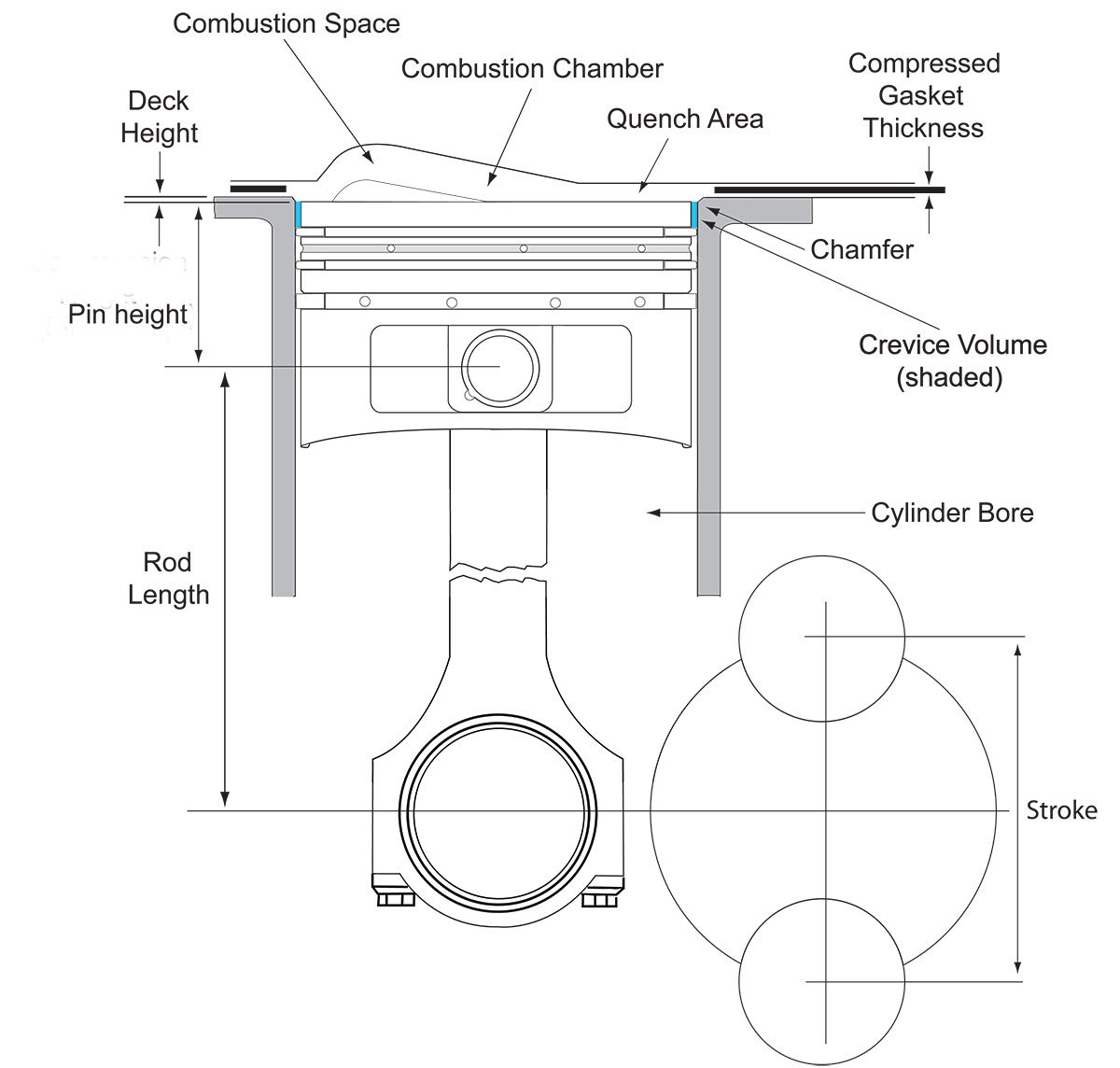

Its more a relative issue to the given hours on the engine and the loss of compression. Thats the volume of the cylinder when a piston is.

Thin Walled Vessel And Thick Wall Cylinder Strength Of The

Compression difference between cylinders. A compression test is not really about measuring the pressure itself to determine the health of the engine. According to my mercury service manual variation of more than 15lbs per sq in. When the needle drifts between 5 and 19 the cause may be a compression leak in the cylinder head gasket between two or more cylinders. A 91 compression ratio cylinder is compressing the air and fuel mixture to about 132 psi at sea level 9x1471323. The regular engine compression test uses a single gauge and measures the maximum instantaneous compression built by that cylinder. Similarly a compression of 85 psi or lower is extremely bad.

A zero reading at idling speed after a 22 reading at high speed indicates worn piston rings. As a general rule a compression of 135 psi or better is excellent. Rather it is more about measuring the pressure differences between cylinders under the same test conditionstypically to help diagnose a problem. If the needle drifts between 5 and 19 there may be a leak at the cylinder head gasket. Furthermore that reading should be above 135 psi. Between cylinders indicates that the lower compression cylinder is in some way defective such as worn or sticking piston rings andor scored piston and cylinder.

An outboard gas engine needs air fuel spark compression and unobstructed exhaust in the right amounts and at the right time. How much varience allowed between cylinderss compression. The most desirable situation is that all cylinders give the same or close to the same reading. Ie a 20 year old engine with 5 difference isnt bad a 10 difference isnt great but okay and a 15 difference should be examined. Atmospheric pressure at sea level is approximately 147 psi. A compression ratio is exactly what it sounds likea ratio where youre compressing the maximum cylinder volume into the minimum cylinder volume.

As the piston travels up and down in the cylinder the piston rings seal against the cylinder wall so the airfuel mixture can be compressed at the top of the cylinder on the upstroke. A compression test uses the engine turning to generate the compression in the cylinder for the compression stroke in which both intake and exhaust valves are closed.