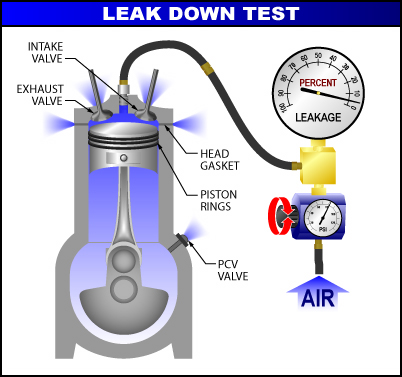

Both tools are designed to measure cylinder pressure in order to highlight and diagnose engine problems. Finally a cylinder leak down tester relies on an external supply of compressed air.

Cog C10 Technical Page Leak Down Tester

Compression and leak down tester. A compression tester is a stand alone tool that relies on the engines compression to build pressure in the cylinder. The leakdown tester is less common and you need to get a. Instead of measuring the engines ability to create pressure compressed air is introduced into the cylinder through the spark plug hole. A compression tester is a stand alone tool that relies on the engines compression to build pressure in the cylinder. A leak down tester relies on an external supply of compressed air. Please share dannysengineportal news.

Amazons choice for compression leak down tester cheesea new heavy tu 21 cylinder leakage leak detector engine compression tester gauges set 39 out of 5 stars 35. A leak down test uses a set of gauges and pressurizes the cylinder with air and measures how much of that air is escaping. Compressed air or nitrogen is fed into the gauge and the gauge is calibrated against a zero reference no air leakage. Pressurized air is supplied to each cylinder and in moments displays a rate of leakage measure from 0 to 100. A leak down test is performed with a special gauge and manifold set. The regular engine compression test uses a single gauge and measures the maximum instantaneous compression built by that cylinder.

A compression test uses the engine turning to generate the compression in the cylinder for the compression stroke in which both intake and exhaust valves are closed. It consists of a calibrated pressure gauge and a pressure regulator and adapters to connect it to the spark plug hole. Compression tests should normally be done with all spark plugs removed to maximize cranking speed. You cant use a leak down tester without an air compressor or nitrogen tank. A leak down test works by putting air pressure into the cylinder and the gauge measures the amount of pressure drop or leakage in the cylinder. First you must remove the spark plug then set the cylinder that you wish to test to tdc compression top dead center of the compression stroke.

If you stopped reading right now a novice might choose a compression tester. Then install the leak down test adaptor and connect to the gauge. The compression tester is the more common of the two and you can usually rent one at your local auto parts stores loan a tool program. An engine leakdown test is a compression test in reverse. Compression testing is a crude form of leak down testing which also includes effects due to compression ratio valve timing cranking speed and other factors. This cylinder leak down tester gauges leak down tests more accurately than standard compression tests.