The cylinder leak down test reading is expressed in a percentage. Leak down readings of up to 20 are usually acceptable.

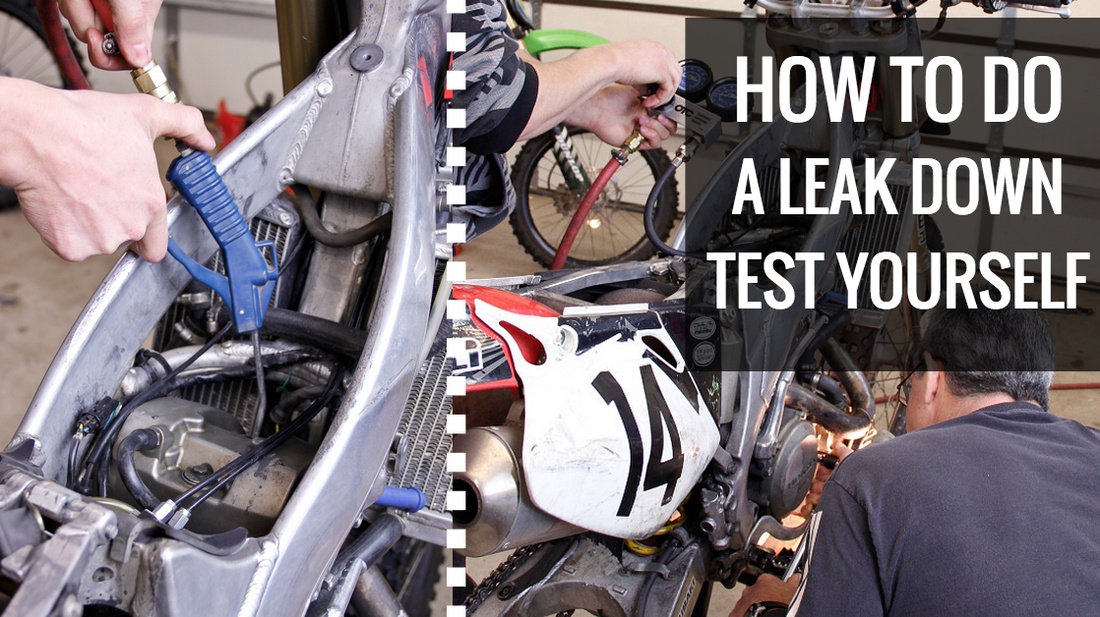

How To Perform A Leak Down Test On A Motorcycle How To

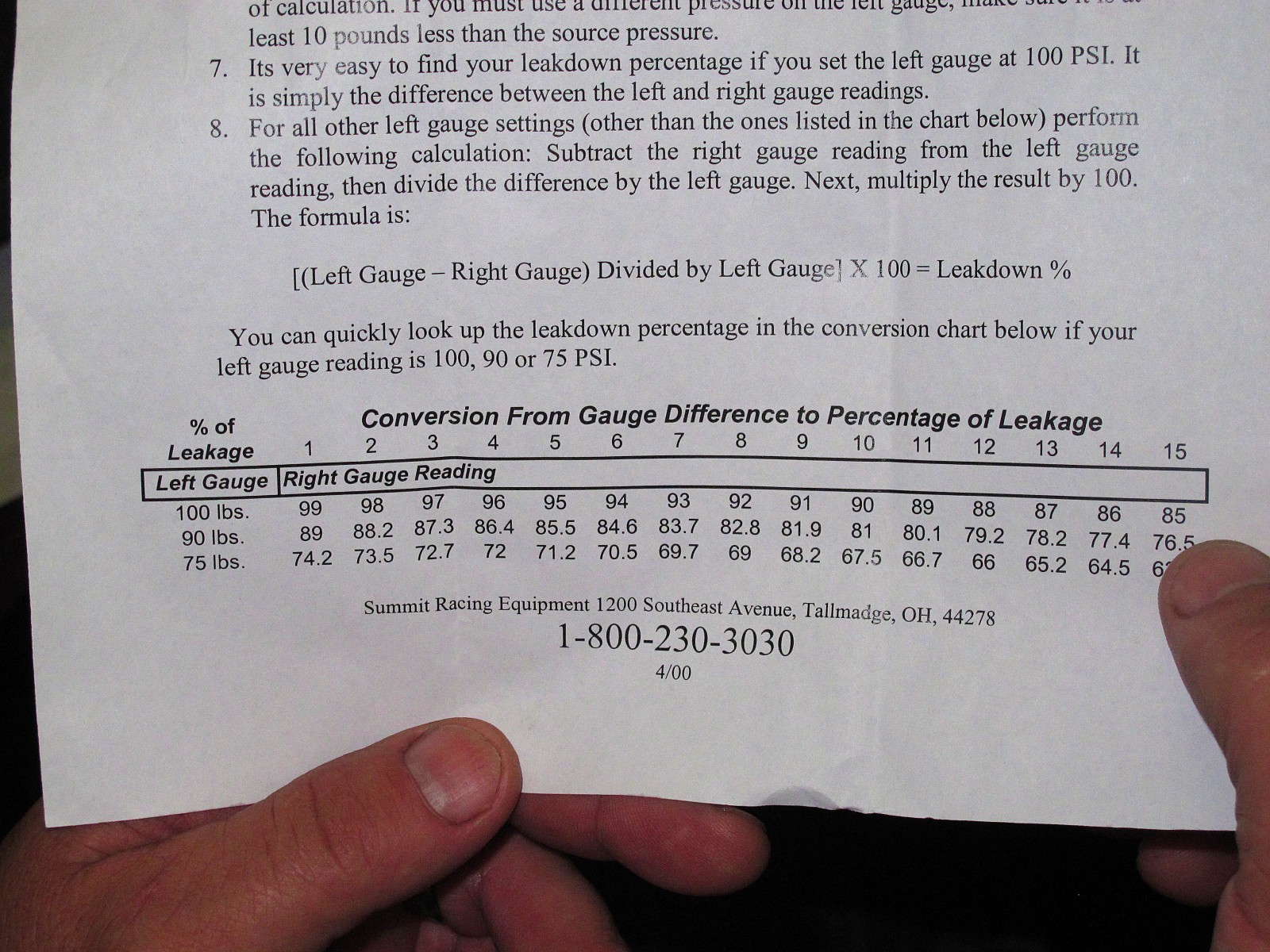

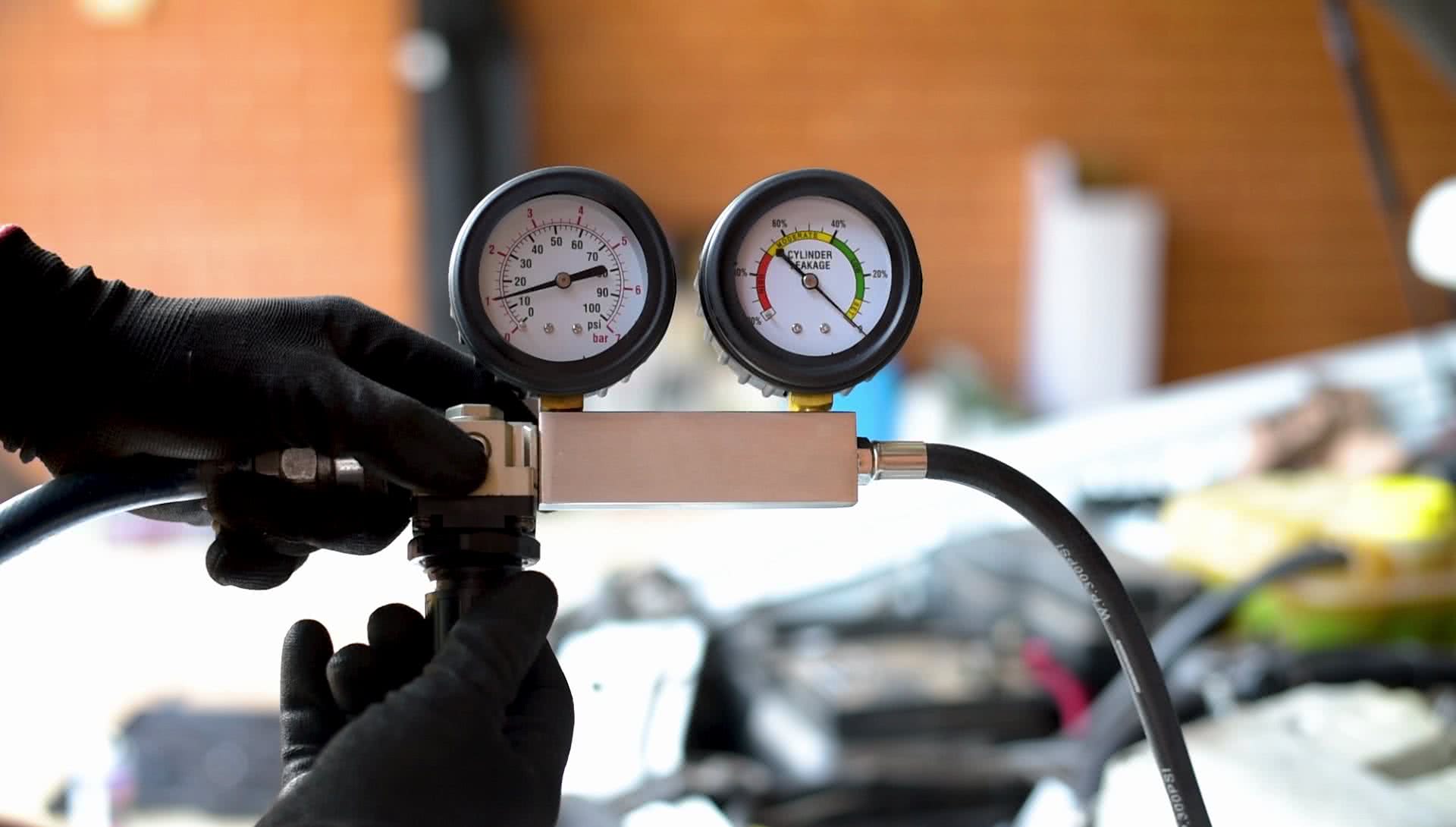

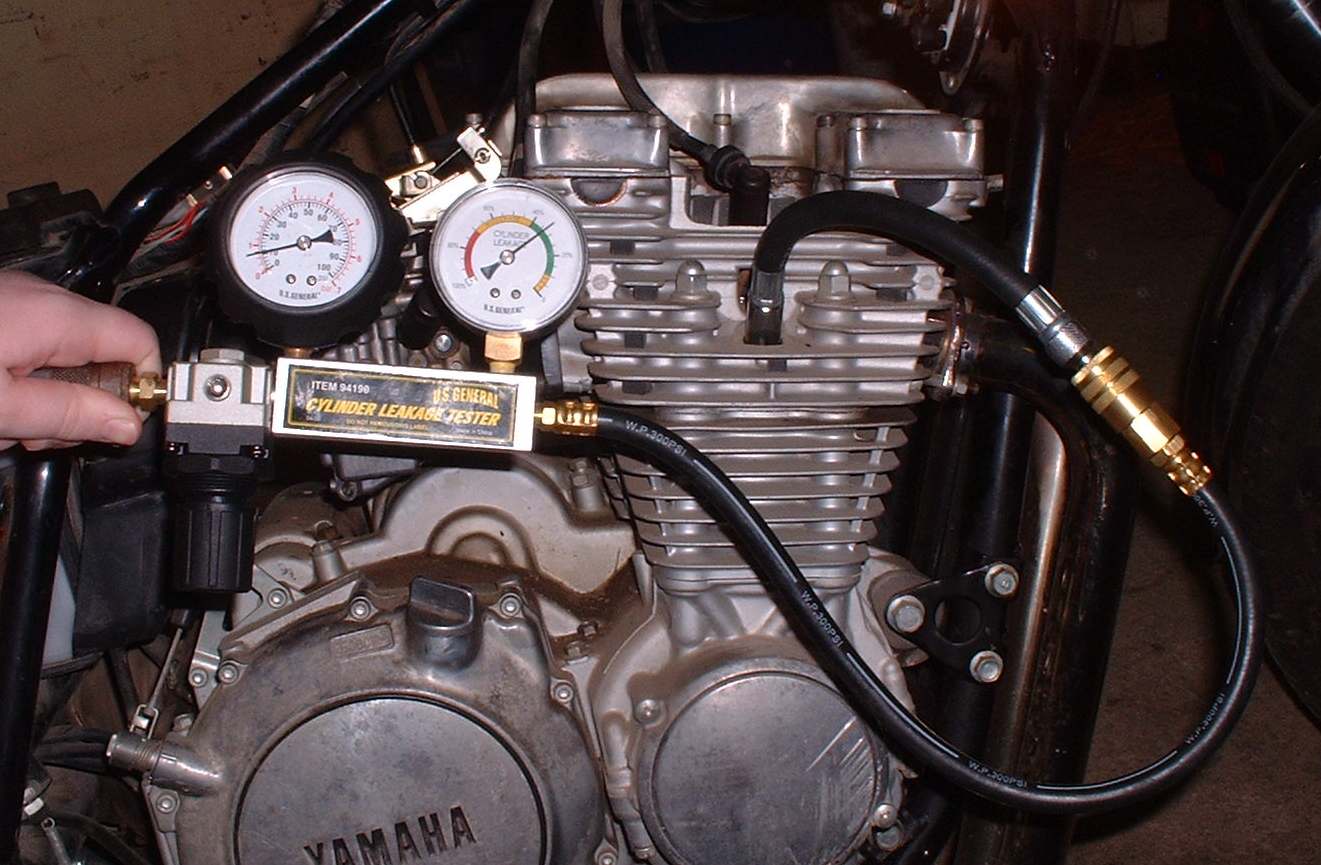

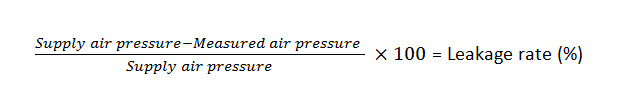

Acceptable leak down percentage. In simplified terms if air is pumped into the cylinder at 100 psi and the gauge reads 97 psi then the leak down percentage is 3. One test you could try is to pump a shot or two of engine oil into a cylinder crank the engine over for a dozen rotations or so and try the compression test again. To get back to your question as long as the cranking compression is relatively equal i wouldnt worry much about the 40 percent leakage. Even for normally aspirated engines respectable leakage numbers would be anywhere from 8 to 12 percent with a variation between cylinders of 4 to 5 percent but its possible the variation could. Racing engines would be in the 1 10 range for top performance although this number can vary. The tester is connected to an air source and is attached to the engine through the spark plug hole.

Doing a leak down test is a fairly simple matter. So the great thing about the cylinder leak down test is that. Leakages over 20 generally indicate internal repairs are required. Furthermore the readings are not affected cam timing or even engine cranking speed. If you find one or more cylinders are below the 10 percent range of the others squirt a little oil down the cylinders and try again. Ideally a baseline number should be taken on a fresh engine and recorded.

Consequently good cylinder leakdown readings should be below 5 8. If the pressure comes up significantly the problem may be worn. It deals with how well the cylinder is sealing and nothing else.

.ashx?modified=20180416133121)