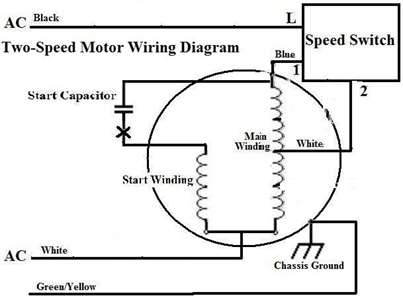

One way to solve the single phase problem is to build a 2 phase motor deriving 2 phase power from single phase. Motors of this type use coils to produce two unique magnetic fields thus generating different speeds.

Speed Control For Shaded Pole And Psc Motors How They Work 039

2 speed single phase electric motor. The induced current in the strap opposes the change of flux through the coil lenzs law so that the maximum field intensity moves across the pole face on each cycle. Disconnect the single phase motor from the power source. Heavy duty steel or cast iron frames. The speed the motor turns is determined by the voltage it gets from the power source. Atv312hu22m2 from schneider electric at allied electronics automation covid 19 update during this time while we remain open and shipping thousands of products daily the safety of our team customers and communities are our top priorities. One or two winding.

California transparency in supply chain act of. Designed for use in applications in which multiple speeds are required. This is called a permanent split capacitor motor. Literature 501 stock product catalog. Permanent split capacitor induction motor. One contactor burnt for high speed and a replced contactor does not engange originally the coils re fed with a nutural and the one i replaced is only working with a phase.

That will burn out the motor windings. A common single phase motor is the shaded pole motor which is used in devices requiring lower torque such as electric fans microwave ovens and other small household appliances. A wide variety of single phase two speed electric motor options are available to you such as car home appliance and construction hoist. Kindly email me the diagrams for star deltor and direct online for a 3speed 1directon 3ph motor have two of them in a bow cutter. Part of each pole is encircled by a copper coil or strap. The top countries of suppliers are.

Please help how to go about this. Single phase motors are used when a three phase system is not available andor for limited power they are generally used for powers under 2 kw or 3 kw. Reduce the voltage and the speed of your single phase motor decreases. This requires a motor with two windings spaced apart 90 electrical fed with two phases of current displaced 90 in time. Two speed motors use a switch oriented towards either high speed or low speed coil. Increase the voltage and the speed of your motor increases.

Three phase motors commonly see more use in industry since their power is over 150 greater than that of a single phase motor and a three phase rotating magnetic field is generated. While running a single phase motor can be noisy and generate. As the machinist you are responsible for determining the speed at which youd like the motor to run. In this motor small single turn copper shading coils create the moving magnetic field. Use a knife and cut the wire that connects. Electric motors let us obtain mechanical energy in the simplest and most efficient manner.

Never increase the voltage above the input voltage labeled on the motor. Install a variable rheostat and you can control your motors speed. Robust 2 horse power 110 volt 2800 rpm single phase electric motor 1 phase air compressor motor overload protector condensercapacitor. View in online catalog.